Series submersible sewage pump WQ

Sewage pump is a kind of pump product which is connected with the motor and works under the liquid at the same time. Compared with the general horizontal pump or vertical sewage pump, the sewage pump is compact in structure and occupies a small area. The installation and maintenance are convenient. Large sewage pumps are generally equipped with automatic coupling devices for automatic installation, which is quite convenient for installation and maintenance. Long continuous operation time. As the pump and motor are coaxial, the shaft of the sewage pump is short, and the weight of the rotating parts is light, the load (radial) on the bearing is relatively small, and the service life of the sewage pump is much longer than that of the general pump. There are no cavitation damage, irrigation and diversion problems. In particular, the latter point brings great convenience to operators. Low vibration noise, low motor temperature rise, no pollution to the environment.

Please pay attention to editing and broadcasting

1. Make sure the operating environment of the clean water pump, and select the correct pump type (generally wet type and dry type)

2. Calculate the required lift of the pump. Sometimes, customers calculate the flat conveying distance into the head, which is wrong. The head can only be calculated after the flat conveying distance is multiplied by the friction coefficient.

3. Pipe elbow wear and pipe friction should be included, which are different in actual situations, and it is also troublesome to calculate accurately, so it is recommended to leave some space to ensure that the water pump can pump water.

4. If the stainless steel sewage pump is selected, the pH of the water quality, including particle diameter, should also be clarified, and the appropriate stainless steel material should be selected. Generally, 304 material is suitable for PH4~10. It is recommended to use 316 or 316L stainless steel beyond this range.

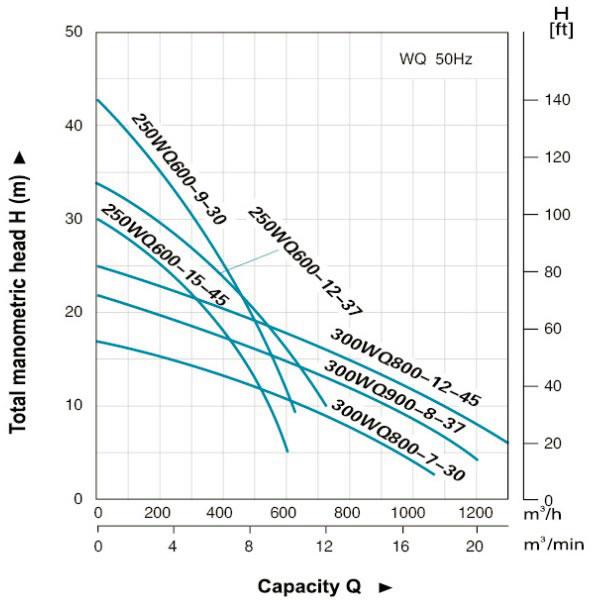

5. The water pump must be used within the rated lift range to ensure that the motor is not overloaded.

For example, the actual required lift is 30 meters, but using a pump with a standard lift of less than 30 meters to pump water belongs to the wrong use method, which will cause overload of the motor. In serious cases, the motor will be burned.

6. The water pump pipe must be unblocked. If the pipe is blocked, the motor will also be overloaded, and in serious cases, the motor will be burned.

Scope of use

① Wastewater discharge of enterprises.

② Discharge system of urban sewage treatment plant.

③ Metro, basement, drainage station of civil air defense system.

④ Sewage discharge of hospitals, hotels and high-rise buildings.

⑤ Sewage drainage station in residential area.

⑥ Discharge of slurry from municipal works and construction sites.

⑦ The water supply device of the waterworks.

⑧ Sewage discharge from livestock farms and rural farmland irrigation.

⑨ Supporting exploration mines and water treatment equipment.

⑩ Instead of carrying people on their shoulders, they suck and send river mud.

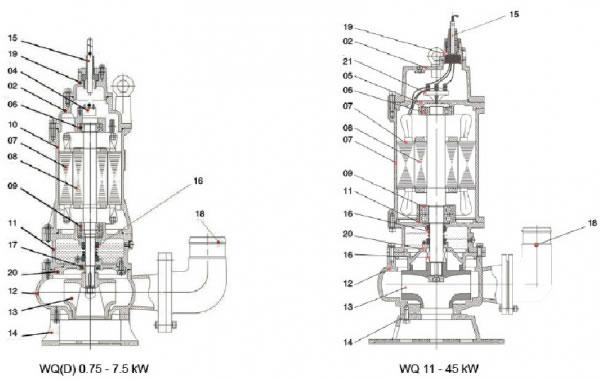

| No. | Part | Material |

| 1 | Handle | Steel |

| 2 | Upper Cover | Cast Iron |

| 3 | Capacitor | |

| 4 | Thermal Protector | |

| 5 | Upper Bearing Seat | 304/316/316L |

| 6 | Bering | |

| 7 | Stator | |

| 8 | Rotor | |

| 9 | Bearing | |

| 10 | Motor Body | 304/316/316L |

| 11 | Bearing Seat | 304/316/316L |

| 12 | Pump Body | 304/316/316L |

| 13 | Impeller | 304/316/316L |

| 14 | Base | 304/316/316L |

| 15 | Cable | |

| 16 | Mechanical Seal | Sic-Sic/Carbon-Ceramic(< 7.5kw) Sic-Sic/Sic-Sic(>7.5kw) |

| 17 | Oil Seal | |

| 18 | Hose Coupling | 304/316/316L |

| 19 | Terminal Box | 304/316/316L |

| 20 | Seal Bracket | 304/316/316L |

| 21 | Wiring Terminal |